Several methods exist for calculating stamping force, and which one to use depends on the specific stamping process and the type of stamping force that needs to be calculated. Here are some common methods for calculating stamping force:

A basic formula for calculating stamping force breaks it down into a sum of several parts, including shearing force, unloading force, pushing force, edge pressing force, and deep drawing force.

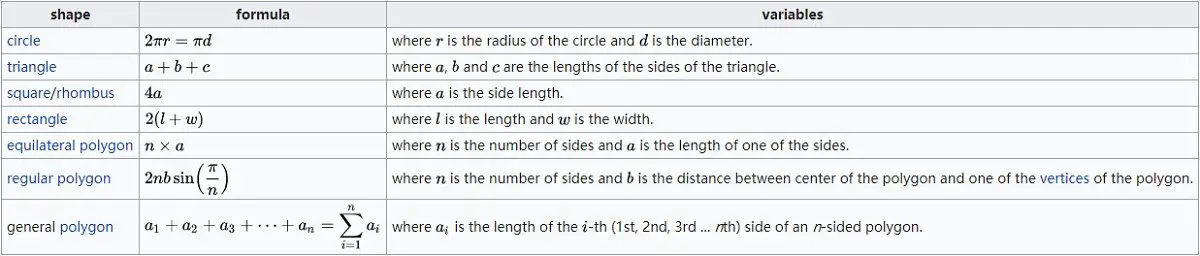

To calculate the stamping force for edge cutting and punching, you can use the formula

where,

Another method for calculating shearing force is the formula P=ltτ, where P is the shearing force (in N), l is the stamping perimeter of the part (in mm), t is the thickness of the part (in mm), and τ is the shear strength of the stamping material (in MPa).

For specific scenarios of calculating shearing force, if the shape of the part is small and the punch uses a flat cutting edge, the formula F=Ltτ can be used to calculate the shearing force, where F is the shearing force (in N), L is the perimeter of the sheared part (in mm), and τ is the shear strength of the stamping material.

How to calculate the force (tonnage) of a punch press machine for power press machine?

I believe the following press tonnage calculator can be used to calculate the required punch force (blanking force) for your workpiece.

P.S: If you want to calculate hydraulic press tonnage, you can use our hydraulic press tonnage calculator.

Related calculator: V & U-shaped Bend Force Calculator

If you need to punch round, square, or any other type of hole through a given metal thickness, you’ll need to determine the punching force required to accomplish this task.

To calculate the required press tonnage, you can use the following punching force calculation formula, which is also applicable for blanking force calculation.

Press Tonnage (KN) = Perimeter (mm) * Plate Thickness (mm) * Shear Strength (kn / mm2)

Converted into metric tons: dividing the result of KN by 9.81

Common materials’ shear strength are as follows: unit: KN/mm2

| Aluminum | Brass | Low Carbon Steel | Stainless Steel |

| 0.1724 | 0.2413 | 0.3447 | 0.5171 |

For various shear strength table, you can check out the following post:

e.g: If punching one square hole in the 3mm thickness low-carbon steel plate, side length 20mm, you will get:

Punch Force (KN) = 80 x 3 x 0.3447 = 82.728 KN Convert into tonnage: 82.728 KN ÷ 9.81 = 8.43 Ton

For further information about shearing strength, including how to calculate it, you can refer to the Wikipedia article.

The formula mentioned can also be applied as the cutting force formula in press tooling or as the formula for determining the force required to punch a hole.

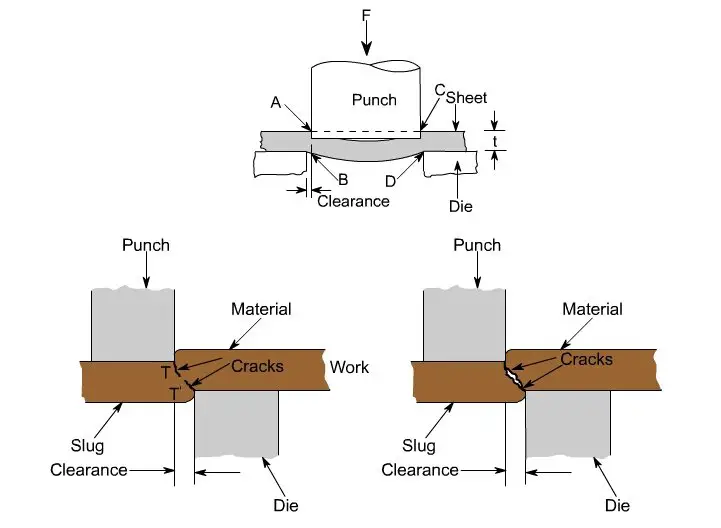

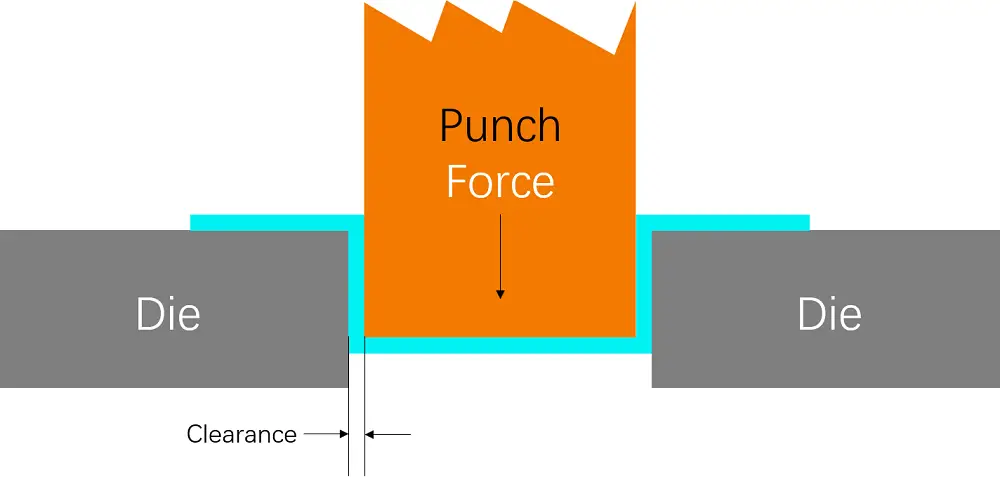

The clearance between the punch and dies is a critical factor in the punching process, and it is represented by the total difference.

For instance, suppose you are using an ø12 upper die and an ø12.25 lower die. In that case, the optimal clearance should be 0.25mm.

If the clearance is not proper, it can reduce the die’s service life, cause burrs, and lead to secondary cutting. An irregular opening can also increase the demounting force.

Moreover, the die clearance depends on the material and thickness, and for carbon steel plates, it is recommended to use a value between 12-18% of the thickness.

See also:

If there are no special requirements for the CNC punch, you can refer to the following table for selecting the die clearance.

| Thickness | Mild Steel | Aluminum | Stainless Steel |

| 0.8-1.6 | 0.15-0.2 | 0.15-0.2 | 0.15-0.3 |

| 1.6-2.3 | 0.2-0.3 | 0.2-0.3 | 0.3-0.4 |

| 2.3-3.2 | 0.3-0.4 | 0.3-0.4 | 0.4-0.6 |

| 3.2-4.5 | 0.4-0.6 | 0.4-0.5 | 0.6-1.0 |

| 4.5-6.0 | 0.6-0.9 | 0.5-0.7 | / |

As the founder of MachineMFG, I have dedicated over a decade of my career to the metalworking industry. My extensive experience has allowed me to become an expert in the fields of sheet metal fabrication, machining, mechanical engineering, and machine tools for metals. I am constantly thinking, reading, and writing about these subjects, constantly striving to stay at the forefront of my field. Let my knowledge and expertise be an asset to your business.